Get Your Quote

Adjustable Spreader Beams – Lifting Spreader Beams

- Available in 5 to 100 ton capacities

- Can be customized to 20 ft or 40 ft max spreader length

- No tube cutting

- Easier drilling

Description

ELT is proud to introduce you to our line of Made In The USA adjustable spreader beams and lifting spreader beams! Made from the highest grade materials and designed to OSHA and ASME B30.20 specifications, our adjustable spreader beams and lifting spreader beams are your best choice for safety and manufacturer quality.

Spreader beams are a popular and functional option for stabilizing heavy or large footprint lifts. While their design requires more headroom than a center bail lifting beam, the load is transferred directly from the top rigging slings to the bottom rigging slings. This means that the spreader beam, when used appropriately, will only experience compression forces instead of vertical load throughout the beam. The result is a much lighter (and often more economical) lifting device.

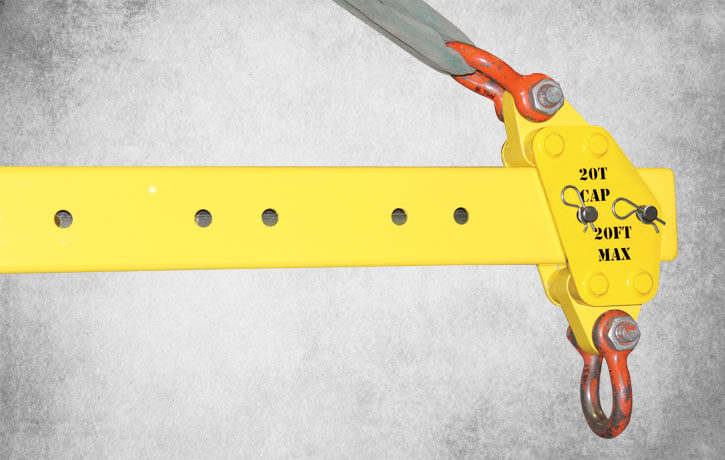

ELT’s ASB Adjustable Spreader Beam System is a best in class, unique to the industry solution that allows the utmost level of flexibility in rigging arrangements without sacrificing performance. The system includes two brackets, each with two shackles mounted to beckets, secured to a tube steel beam via pins mounted in drilled holes. The brackets feature a permanent information plate that features working load limit and required tube steel specifications. ELT offers the system with a pre-drilled beam, and undrilled beam to allow for specific, field determined orientation, or as brackets alone. The nature of the flat sided tube steel makes field adjustments to hole spacing easy, maximizing jobsite versatility. Tube steel sections can also be cut to convenient lengths for specific applications. As the design of the brackets allows them to slide freely over the tube steel, a clean end cut is not imperative as it is with traditional pipe end cap beam designs.

Working load limits for the system ranges from 10,000 to 200,000 capacities with custom designs possible to accommodate the situation. The system comes in standard lengths of 20’ and 40’. The system is capable of maintaining its full working load limit throughout its reach capacity, unlike most spreader beams readily available in the marketplace. The 40’ model can be equipped with an optional center coupler that allows the rigger to use two 16’ sections of tube steel along with the 12’ coupler section to achieve spread distances of 5’ to 40’ while still maintaining manageable beam lengths to better facilitate trouble free transport.

The ASB Adjustable Spreader Beam System and lifting spreader beams are manufactured in the USA and are designed to meet or exceed ASME B30.20 and OSHA standards. The Brackets are load tested to 125% of working load limit before shipping and will include the supporting certification paperwork.